Welcome back to the eighth installment of Wisdom Behind The Wood! When purchasing a cutting board, the first question is likely centered around whether the board is end grain or edge grain. In this installment, I'll explore the differences between edge grain and end grain cutting boards and the benefits of both for your purchasing decision.

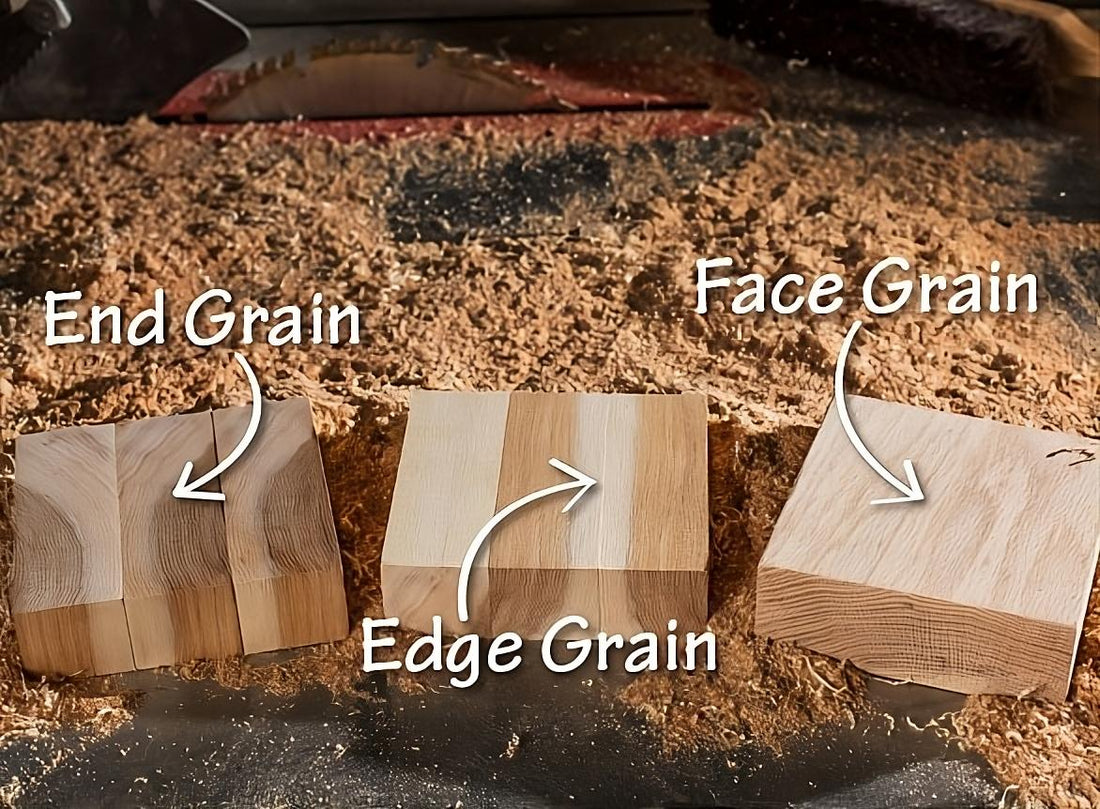

What is end grain and edge grain?

A tree is formed from a multitude of tiny vesicles known as xylem. Their function is to transport water from the roots of the tree into the leaves. They function and look similar to very long thing straws, using the evaporation of water from the leaves to pull water up the height of the tree. If you have ever counted the rings of a tree to determine its age, you have counted a band of vesicles that were produced during the winter (thus making them smaller and darker due to decreased water transportation).

An end grain cutting board utilizes the end pieces of a log or board as a chopping surface. In contrast, an edge grain board uses the edge pieces of a log or board as its chopping surface.

What is the difference between edge grain and end grain cutting boards?

On the surface, an end grain board is significantly more expensive. This increase in cost is due to the both the increased labor and materials in fabricating an end grain cutting board, but with those costs come a myriad of benefits.

End grain cutting boards are significantly gentler on knife edges and have self-healing properties. Think back to the bundle of straws, it is much easier and less damaging to wood to slice into ends of those straws then across them. This is also why end grain cutting boards are significantly more durable than their edge grain counterparts. As you cut an edge grain cutting board you are severing the wood fibers or straws. Repeated cuts will eventually lead to chip out, roughness, and scarring. Similarly to plastic cutting boards, these gouges can lead to food particles and bacteria becoming trapped in the scars. This can make cutting boards difficult to clean and disinfect.

Are end grain cutting boards antibacterial?

End grain cutting boards resist deep scarring and also have an added benefit of being antibacterial. This goes back to the vesicles of the board, which will carry bacteria into the center of the board. Once inside the board, the bacteria will die due to lack of moisture over the course of a few days. Dean Cliver former faculty member of UW-Madison Department of Food Microbiology and Toxicology said: "Wood is intrinsically porous, which allows food juices and bacteria to enter the body of the wood unless a highly hydrophobic residue covers the surface. The moisture is drawn in by capillary action until there is no more free fluid on the surface, at which point immigration ceases. Bacteria in the wood pores are not killed instantly, but neither do they return to the surface." in an article titled Cutting Boards in Salmonella Cross-Contamination published in the Journal of AOAC INTERNATIONAL.

Looking for an end grain board? Try my personal favorite, a 16" x 22" Walnut End Grain Cutting Board. Its size makes a it a good daily driver and the walnut really impresses for entertaining.

What are the benefits of an edge grain cutting board?

End grain cutting boards boast a long list of benefits that tend to outweigh their edge grain counterparts. It is important to note that edge grain boards do have a few use cases where they are the superior choice. Their low cost makes them easier to use for more messy or destructive tasks. Many customers find using edge grain boards with destructive serrated knives or messy bbq ideal. This leaves their end grain boards in better shape for vegetable or meat chopping/slicing.

If you're looking for a good edge grain cutting board, check out ours here. Our edge grain cutting board is reversible and comes equipped with a 12" ruler laser engraved on the face and finger grooves for easy handling.

About Nolan Russell

Nolan Russell is the Operations Manager at The Boardsmith. His blog segment dives deeper into the trees, lumber, and the science that make our butcher block the best in the world. Nolan is a Certified Arborist, former Tree Care Professional, and all-around tree nerd.